Gain efficiency save CO₂

Terms such as ecological footprint, climate change, energy efficiency, and CO2 emissions are topics that are mentioned daily in the media today. Not only in the media but also in our everyday lives, these terms are becoming increasingly apparent.

It is the responsibility of everyone to make a positive contribution. We, as Bächli, can also contribute something with our products. Transformers can be designed in various ways, including being very energy efficient. An energy-efficient product generates much less CO2 emissions during operation and can also have a positive balance in terms of life cycle costs due to its longer life horizon.

We are happy to explain how this works in this blog. One thing is already clear: energy efficiency and economy do not exclude each other!

Share

The Relationship between Losses in Inductive Wound Goods and CO₂

Losses in the form of thermal heating occur in all electrical components.

In inductive components, including transformers, losses occur in the form of thermal heating. Despite their high efficiency, sometimes up to a maximum of 99%, the losses of transformers in Central and Northern Europe average of 5.7%. This energy not only needs to be additionally produced but also costs natural resources. Electrical energy heats the air, thus burdening the climate. This heated air is referred to as CO2 emissions.

Approximately 84% of all anthropogenic (human-made) CO2 emissions come from the areas of agriculture, transport, electricity and heat production, and industry. In 2016, Switzerland ranked seventy-first globally, producing 38 million tons of CO2 per year. Per capita, this amounts to about 5 tons of CO2 emissions per Swiss citizen (source: myclimat.org).

In this blog post, we often use the term CO2 equivalent. This indicates the amount of emission gases produced during energy production. According to a study by the Institute for Economic Law, one kilowatt-hour of electricity (1kWh) in Switzerland, Northern, and Western Europe corresponds to a carbon dioxide amount of 590g. This is our starting value for the following comparisons.

Use of Energy-Efficient Wound Goods

The efficiency of a transformer can be influenced by various parameters such as material selection, challenge to achieve the best possible calculation, or manufacturing accuracy. Of course, this always depends on the technical specifications and requirements regarding space, weight, temperature, cost.

Generally, it can be said that inductive components such as transformers, chokes, and filters already have a high efficiency. However, there is still room for improvement, which can positively influence the energy efficiency of a product.

Our engineers are very competent in this area and help you design the product optimally according to your design criteria but also very sustainably and resource-conserving. Bächli has its own product line for this purpose, the Smart-E-Power® product line. It is the solution for the highest efficiency. The products stand out due to minimal performance losses. This reduces operating costs to a minimum and significantly lowers CO2 emissions.

Smart-E-Power® products are characterized by the lowest possible performance losses: They achieve an efficiency of over 99% from a construction capacity of 25 kVA for 50/60Hz transformers. This reduces maintenance costs to a minimum.

The graphic shows that the Smart-E-Power® product line achieves the best performance in terms of energy losses. This means the absolute highest energy efficiency and the lowest performance losses in this representation.

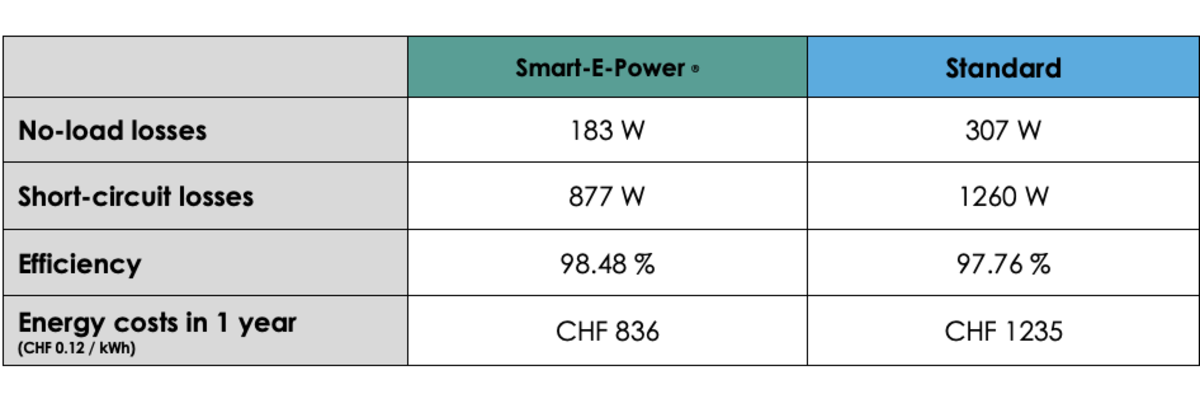

We would like to illustrate this with a product example. Our transformer, a compact 70kVA auxiliary converter transformer, was calculated once as a standard version and once as a Smart-E-Power® product. The basic condition for both variants was limited space capacity with restricted heat development possibilities.

No-load losses occur in the transformer, when no electrical energy is drawn from the connected consumers. It is said that the transformer is running or working idle. The no-load losses are effective 24 hours a day, 365 days a year, and just 1W less results in a saving of about 87kWh. The table shows that the Smart-E-Power® variant has significantly lower performance losses. This results in 40% lower no-load losses per year. Because of this a lot of energy can be saved within a year of operation with the Smart-E-Power® series.

It can be observed that the efficiency of the Smart-E-Power® products is one percent higher than the standard variant. This results in fewer energy losses as the standard product generates about 3,300 kWh more energy losses per year. The lower energy demand means that the annual energy costs are lower. Based on the Swiss energy price of CHF 0.12 per kWh, you can save CHF 400 per year with the Smart-E-Power® product.

Life Cycle Costs

Life cycle costs include all costs incurred over the entire lifespan of a good. These include planning costs, acquisition price, maintenance, operating costs, and disposal fees.

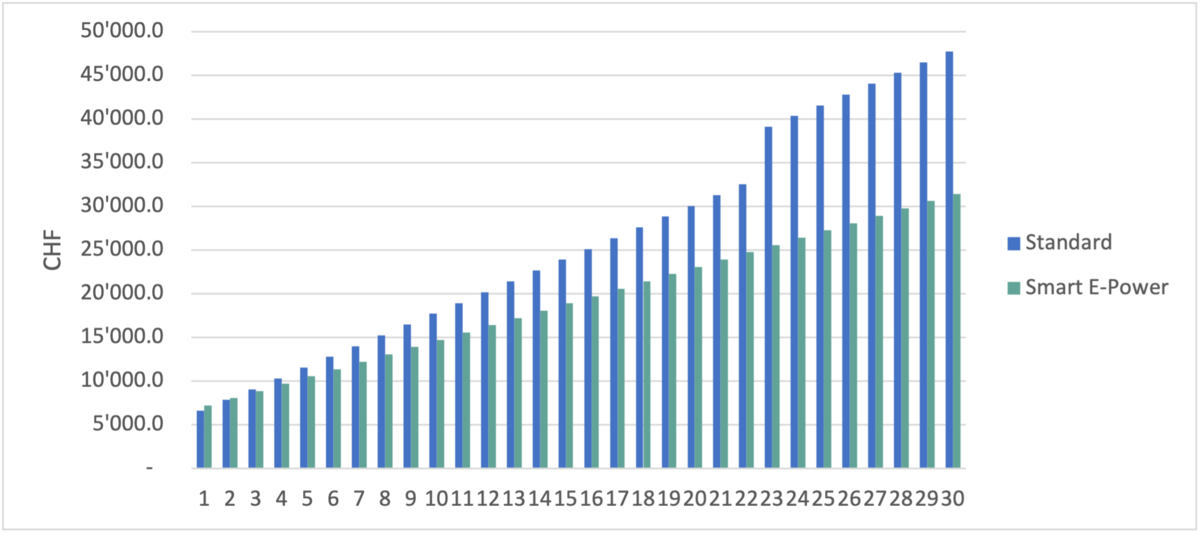

Since the life cycle of the standard product is theoretically shorter than that of an energy-efficient product, it must also be replaced earlier. In our example calculation, this means that we have factored in the acquisition of a new standard auxiliary transformer after 22 years. You can see this in the following graphic based on the sharply increasing costs from year 22 to year 23. The difference between the standard transformer and the energy-efficient variant becomes increasingly apparent.

The life cycle of an energy-efficient product is longer due to the high-quality materials used in the Smart-E-Power® range. Thus, the load on the component is lower, and the service life is increased. In our example, the service life of the energy-efficient transformer doubles compared to a standard product.

The comparison between the entire service life of a standard product and a Smart-E-Power® transformer could save CHF 14’000. This is because the lower energy costs of the efficient transformer and the eliminated acquisition costs of the new standard product, which would fall in year 23, save this considerable sum. You see, with foresight on the total life cycle costs, cost advantages can be achieved, and on the other hand, a significant added value in terms of energy efficiency and CO2 emissions is created.

As you can see from the following graphic, the Smart-E-Power® product already has a positive cost balance after the third year. The slightly higher acquisition costs of the Smart-E-Power® product amortize after a short time. The additional costs of the Smart-E-Power® product can be clearly attributed mainly to the use of high-quality materials.

The calculations were carried out using the example of the 70-kV auxiliary converter in the standard version and the Smart-E-Power® variant. (The disposal costs of the products were not considered in this calculation.)

CO₂ Savings

The CO2 equivalent provides information about the amount of emission gases produced during energy production.

The additional energy demand also means the use of more natural resources, which can lead to higher greenhouse gas emissions and thus harm the climate. Therefore, it can be said that an energy-efficient product leads to better energy efficiency and additionally to more sustainable use of natural resources.

As the name suggests, Smart-E-Power® stands for minimal performance losses and high energy efficiency, which leads to a reduction in CO2 emissions. The calculated CO2 equivalent of the compact Smart-E-Power® auxiliary converter transformer is 6,964 kWh in one year, around 2t less than the compact standard version. This saving corresponds to a round trip from Zurich to New York (8.5h flight time) (/co2.myclimate.org).

As already mentioned, we assume an average service life of 20-30 years for a standard transformer. Taking our example product, the 70kVA auxiliary converter transformer, we can calculate a possible total saving of 99,930t CO2. It is not easy to imagine this amount of CO2, so here is a comparison to a hot air balloon. With the savings of 99,930t CO2, around 13,800 hot air balloons can be filled. You see, it is a huge amount of CO2 savings that can be achieved by choosing the right transformer.

The possibility of making your product more sustainable and energy-efficient does not contradict economic efficiency. Take advantage of this opportunity!