Retrofit

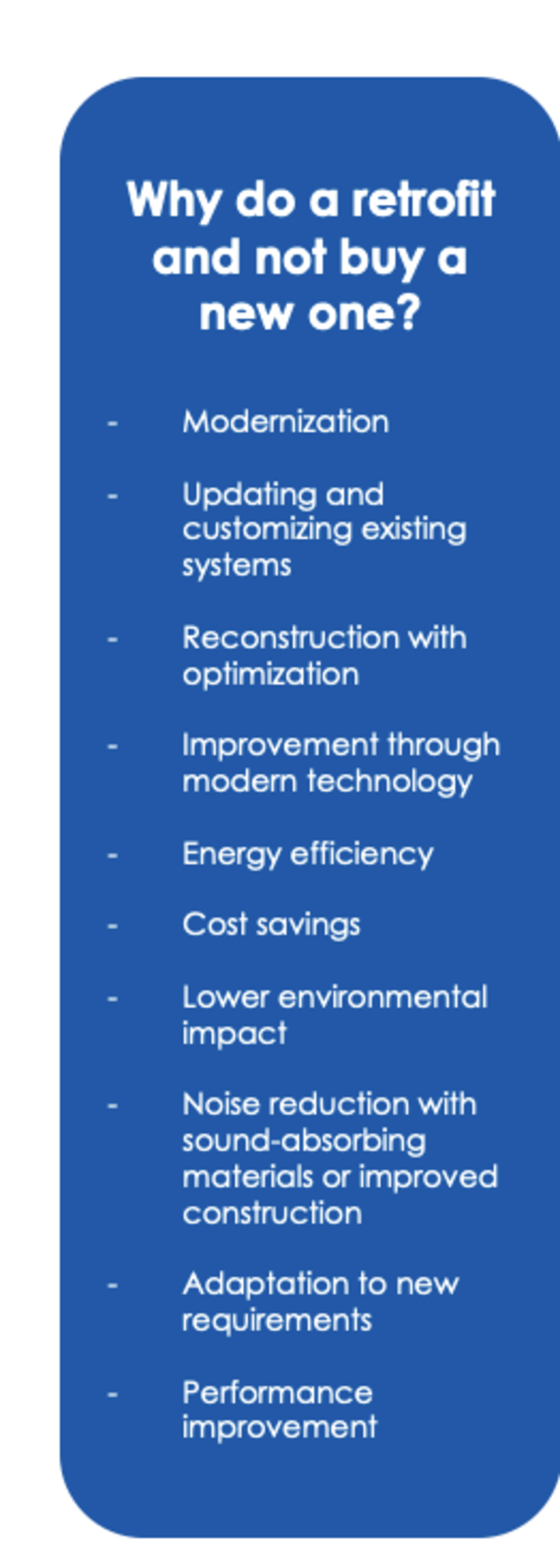

A retrofit product refers to the retrofitting or modernisation of an existing rail vehicle, system or machine with the aim of implementing new technology, modernising components or systems or increasing performance, efficiency, safety and comfort. The product is brought up to the latest state of the art without having to purchase a completely new vehicle, system or machine.

Share

The aim is to achieve an increase in drive power or an improvement in energy efficiency in order to increase efficiency and minimise losses.

The installation of modern safety systems, such as automatic braking systems, collision avoidance systems and better fire protection measures, increases safety in and around the system, train or machine. Over the course of time, safety regulations, standards and provisions have also become stricter and changed. This can also be taken into account during a retrofit.

By upgrading the interior, e.g. with new seats, improved air conditioning systems and a modern passenger information system, the increased needs of operators or passengers can be catered for. In the case of wrapped goods, there is hardly any direct impact on the operator or passenger. However, optimisations can be sought in terms of handling and installation.

By replacing outdated and high-maintenance components with new, more maintenance-friendly systems, maintenance costs can be reduced and reliability increased. In addition, life cycle costs are reduced, which is a considerable cost factor.

By extending the service life of a vehicle or machine with the help of a comprehensive overhaul and renewal of critical components, the service life is extended. In this way, the machine or vehicle can be kept in reliable operation for several more years.

These five optimisations enable the machine, system or train to remain in operation for several years and ensure reliable operation. This enables a long-term planning phase for the replacement of the component, as well as a predictable investment for this major purchase.

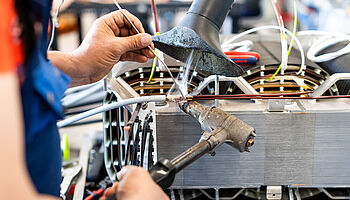

Retrofitting refers to the modernisation or adaptation of existing systems or devices to current technical standards or requirements. Retrofitting measures can make perfect sense when rebuilding or remanufacturing a transformer.

Transformer technology has evolved over time, leading to improved designs and materials. Through retrofitting, older transformers can be updated with modern technologies and materials to improve their performance and efficiency.

New transformer designs can also offer improved energy efficiency, resulting in lower losses and more efficient power transmission. Retrofitting older transformers can realise these efficiency benefits, which can lead to cost savings and a reduced environmental impact.

Reduced noise development can certainly be incorporated when modernising a transformer. Noise is particularly important in environments where noise levels need to be minimised. Retrofitting older transformers with sound-absorbing materials or improved designs can reduce noise levels.

In some cases, it may be necessary to adapt the size of a transformer to changed requirements. By retrofitting older transformers, they can be adapted to new requirements, e.g. to cope with higher power or to take space restrictions into account. Furthermore, new materials and designs help to improve the heat dissipation of transformers, resulting in lower heat generation and improved performance. By retrofitting older transformers, these benefits can be realised, for example by improving the cooling system or implementing more efficient cooling methods.

Overall, retrofitting older transformers can help improve their performance, efficiency and reliability without the cost and effort of full replacement. However, it is important to carefully consider which retrofit measures are best suited to fulfil the specific requirements of the transformer and the objectives of the project.

A retrofit is much more cost-effective than purchasing new products. This is because certain components can often be reused and the existing system also avoids many teething problems, which are often expensive.

With a service life of 40 years since production, the transformer or choke generally already has a long service life. However, the decision in favour of a retrofit extends this even further. Many of the individual components used in a transformer can be recycled or in some cases can even be used a second time when building a retrofit product. These effects also greatly reduce the amount of waste.

The existing product eliminates many development and design services. In addition, there is the possibility of reusing certain items, which can save long replacement times, which can lead to a quick ability to act and a resumption of operations.

Retrofitting is a way of making specific improvements and adjustments that meet current needs. The state of the art and that of all components, too, means that technical improvements can be achieved. It is also possible to optimise the weight and size.

As many advantages as the integration of new technologies can bring, there is also the risk that the integration of new components into an existing structure can be technically very challenging. However, thanks to Bächli's experience and the help of calculation and simulation tools, we are able to assess and minimise this risk.

Costs must be kept in mind from the outset. This is because the integration of new ideas and the increase in material prices can cause them to rise unexpectedly. Especially as the combination of old and new poses challenges that need to be clarified technically before they are implemented.