compact transformer

In the world of engineers and purchasers, especially in the machinery and railway industries, efficiency is paramount. When optimizing systems and facilities, space is often at a premium, which is where compact transformers come into play. Bächli AG is a leader in the development and manufacturing of such transformers that not only save space but also offer a variety of advantages.

Share

What does "compact" mean?

For us, "compact" means that the transformer has a small size relative to its power and function. It refers to physical properties such as size, space requirements, and dimensions.

Advantages of Compact Transformers

1. Space Saving

Compact transformers require less space for installation. This is particularly beneficial in environments with limited space, such as substations, switchgear, or applications where space needs to be minimized. This is especially advantageous in residential areas, industrial plants, or vehicles like trains.

2. Flexibility

The compact design allows these transformers to be used flexibly in various locations. They are easier to transport and install, increasing flexibility in project planning and implementation. It also allows for the possibility of using compact transformers for temporary applications, as they can be relocated with minimal effort. Compact transformers can often be customized to the specific requirements of an application, whether in terms of voltage, power, or other parameters.

3. Reduced Installation Costs and High Adaptability

The installation of compact transformers is generally easier and more cost-effective than larger transformers. This is because less space and effort are needed for assembly, leading to savings on installation costs.

Since they are smaller, this also reduces the need for special foundations or support structures, saving time and money.

Due to their lighter weight and compact design, compact transformers are easier to transport. Additionally, the installation of compact transformers requires less effort and time. Being smaller and lighter, they can typically be installed by fewer workers and with less specialized equipment, reducing labor costs and shortening installation time.

Compactly built transformers are often designed to be easily connected to the existing power grid. This minimizes the need for extensive adjustments or modifications to the existing electrical systems, saving on installation costs.

Overall, the compact design of transformers enables simpler and more cost-effective installation, making them particularly attractive when space and budget are limited.

4. Lower Maintenance Costs

Compact transformers often have fewer moving parts and are therefore less prone to wear and failures. This can reduce maintenance costs over the entire lifecycle, as less maintenance and servicing are required.

5. Reliability/Safety

Compact transformers can be specially optimized for specific applications, improving their reliability and lifespan. This is particularly important in critical applications where failures can be costly or dangerous. The compact design and possible integration of protective functions contribute to improving the safety of the system and users.

6. Energy Efficiency

Compactly built transformers are often very energy efficient. The latest technology and high-quality materials are used. During the development and manufacture of compact transformers, advanced technologies and high-quality materials are often used. This allows for minimizing losses during the transformation process and maximizing energy efficiency. For example, more efficient windings, core materials, and insulation methods can be used to improve the transformer's efficiency.

From a constructional perspective, optimization is also achieved. The compact design often allows for optimized construction of the transformer, where the electrical components are arranged closely together. This can minimize line losses since shorter connection paths and less material are required. Moreover, the compact design enables better heat dissipation, lowering the transformer's operating temperature and increasing efficiency.

The compact transformer tends to have lower idle losses, as it is often equipped with modern insulating materials and special coatings that better control the magnetic flux. This reduces magnetic scattering, which in turn reduces idle losses and improves the overall efficiency of the transformer.

Additionally, modern compact transformers are equipped with advanced control techniques that allow precise control of the transformation process. This can help further minimize energy loss by operating the transformer more efficiently and losing less energy as heat.

In many countries and industries, there are strict regulations and standards for the energy efficiency of transformers. Compact transformers are often developed and manufactured to meet or even exceed these standards to offer customers optimal energy efficiency.

Overall, the combination of the latest technology, optimized construction, lower idle losses, improved control techniques, and compliance with efficiency standards leads to compact transformers often being very energy efficient. This is not only good for the environment but can also lead to significant cost savings for the operator, as less energy is wasted and operating costs are reduced.

7. Lower Weight

Compact transformers are usually lighter. This facilitates transport and installation and can also help reduce the load on structures and foundations.

The lighter design of compact transformers often results from the following design approaches:

When designing compact transformers, lightweight yet robust materials are often used. This allows for reducing the transformer's weight without compromising structural integrity or performance. Modern composite materials can be used, for example, to reduce weight while ensuring strength.

The compact design often allows for optimized arrangement of the transformer's internal components. By placing windings, core materials, and other components in an efficient and space-saving manner, the overall weight of the transformer can be reduced without compromising performance.

Advances in construction technology enable compact transformers to be designed to offer optimal strength with minimal weight.

Overall, the choice of materials, optimized design, ideally designed insulation materials, and improved construction techniques result in compact transformers often being lighter than standard transformers.

8. Noise Emission

The noise emission of compact designs is minimized, making their use versatile.

Through optimized construction, fewer moving parts, and improved insulation, compact transformers are often quieter than standard transformers. This is particularly important in applications where noise emissions need to be minimized, such as in residential areas, office environments, or near sensitive equipment or work areas. Additionally, in some industries, there are strict regulations and standards for the noise emissions of transformers. Compact transformers are often developed and manufactured to meet or even exceed these standards, ensuring that noise levels remain within acceptable limits.

Overall, compact transformers offer a range of benefits that can help reduce costs, improve efficiency, and increase flexibility in project planning and implementation.

Applications of Compact Transformers

Compact transformers are used in a variety of applications and industries where space constraints, mobility, or specific transformer requirements exist. Some of the main application areas are:

Industrial Applications

In factories and industrial plants, compact transformers are often used to supply electrical power to machines, lighting systems, and other applications. The compact design allows for efficient use of limited space in industrial environments.

Buildings and Residential Areas

In residential and commercial buildings, compact transformers are used to transform the network voltage into low voltage needed for powering household appliances and lighting systems. Space saving is often a crucial factor, especially in urban areas where space is scarce.

Telecommunications

In telecommunications facilities, compact transformers are used to provide the required voltages for operating devices such as mobile base stations, repeaters, and routers. Mobility and the ability to mount transformers in small enclosures are advantageous here.

Renewable Energy

In solar and wind power plants, compact transformers are used to feed the generated electricity into the power grid. Due to the limited space in such plants, compact transformers are a preferred choice.

Transportation

In transportation vehicles such as trains, trams, ships, and airplanes, compact transformers are used to supply electrical power for driving motors, lighting systems, and other electrical devices. Mobility and robust design are crucial here.

Emergency Power Supply

Compact transformers are also used in emergency power supply systems to ensure that critical facilities such as hospitals, data centers, and industrial plants continue to be supplied with power during outages.

These are just a few examples of the wide range of application areas where compact transformers are used. Their versatility and efficiency make them an important component in various industries and applications.

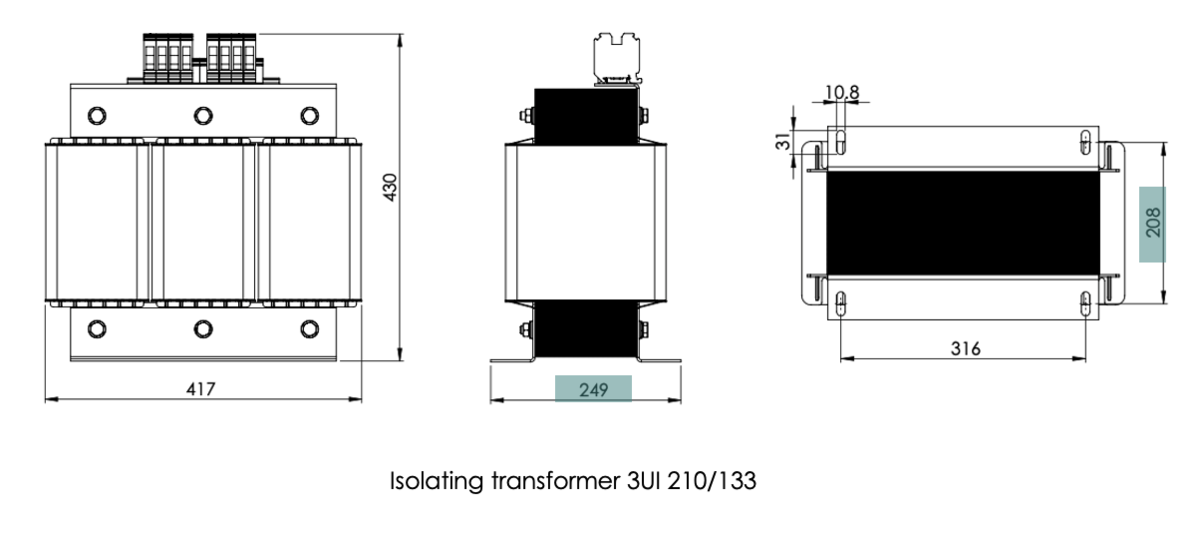

Example of a Compact Transformer

Bächli AG has the capability to design and build transformers very compactly. We would like to introduce the compact design using a 2500VA isolation transformer.

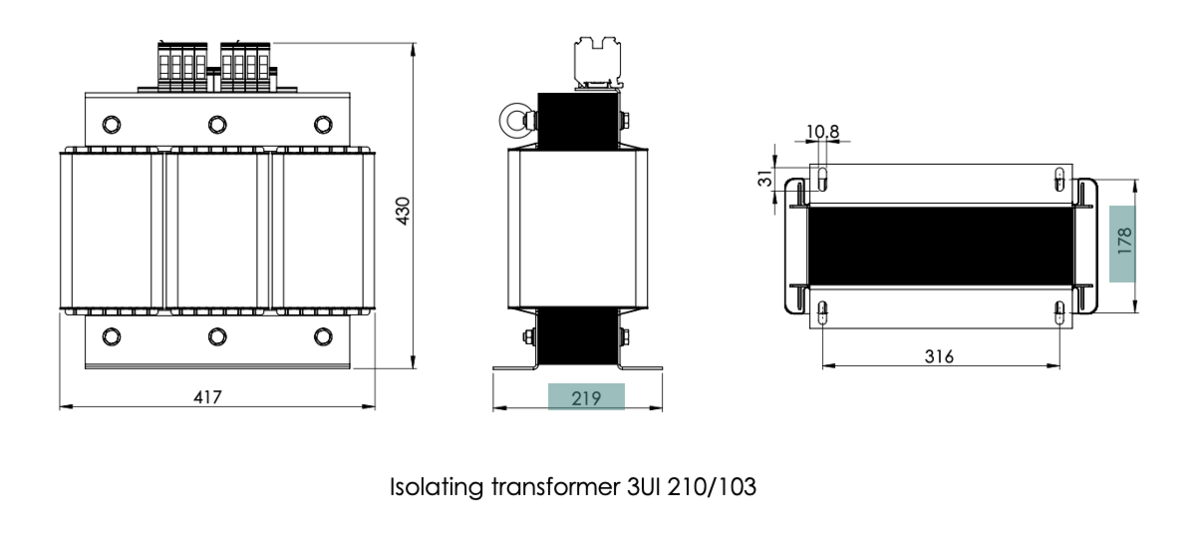

If you purchase the standard isolation transformer 3 UI 210/133 from us, you will get the following product:

Power: 25000 VA

Weight: 154 kg

Dimensions: 417x249x430 mm

However, you can also get the isolation transformer in a compact design from us, namely the product 3UI 210/103:

Power: 25000 VA

Weight: 128 kg

Dimensions: 417x219x430 mm

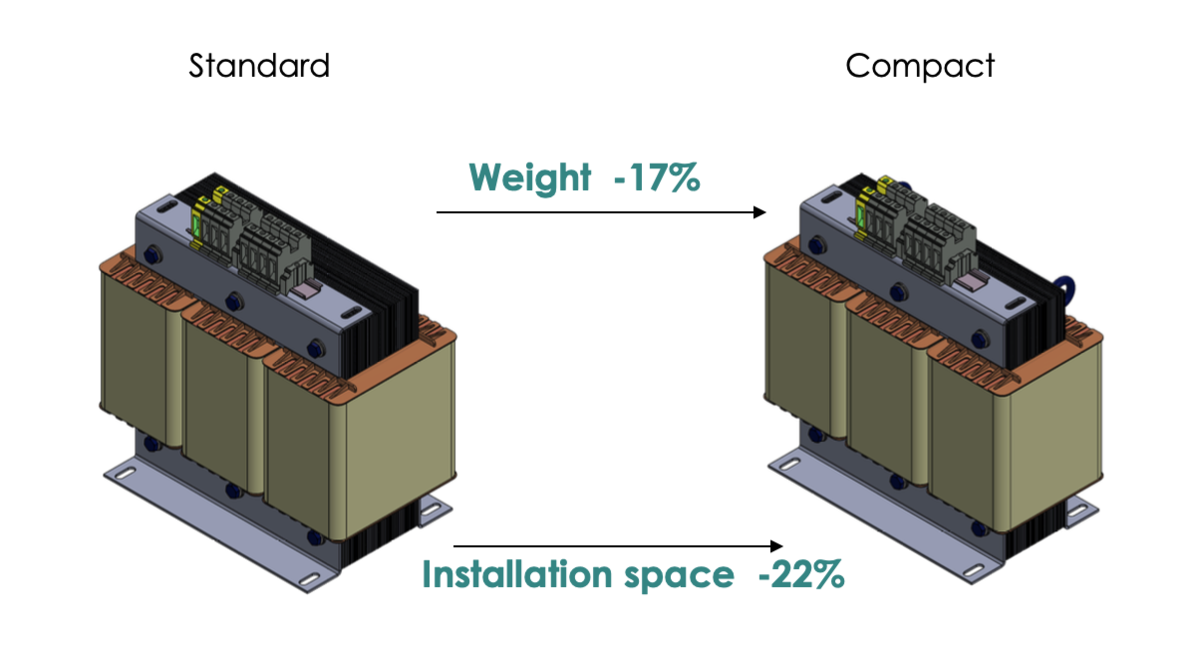

By choosing a compact transformer, you save 26 kg of weight and around 30 mm of space. This makes the transformer slimmer and lighter. Additionally, the compact design transformer is also more cost-effective than the standard version. This way, you save not only space but also procurement costs as a customer.

Overall, compact transformers offer a number of advantages that can help to reduce costs, improve efficiency and increase flexibility in the planning and implementation of projects.

Depending on customer requirements and technical feasibility, it can be adapted in width, depth or height

and can therefore be adapted to the available space.

If you would like to find out more about our compact transformer series, please contact us. We will be happy to provide you with information about our products and look forward to presenting you with an optimum solution for your challenge.