The Transformer - since 200 years the same princip

Share

Mathias Haak's introductory statement is fascinating and may surprise some people:

The induction principle on which the transformer is based has not changed for almost 200 years! At a time when practically everything has changed.

It was in 1831 that Michael Faraday discovered the principle of induction.

Electromagnetic induction

A process in which an electrical voltage and a current flow are generated by moving an electrical conductor in a magnetic field or by changing the magnetic field enclosed by a conductor. Michael Faraday discovered this induction principle when he tried to reverse the way an electromagnet works (current generates a magnetic field) and generate electricity with a magnetic field.

This principle is used in practically all electrical machines, including transformers.

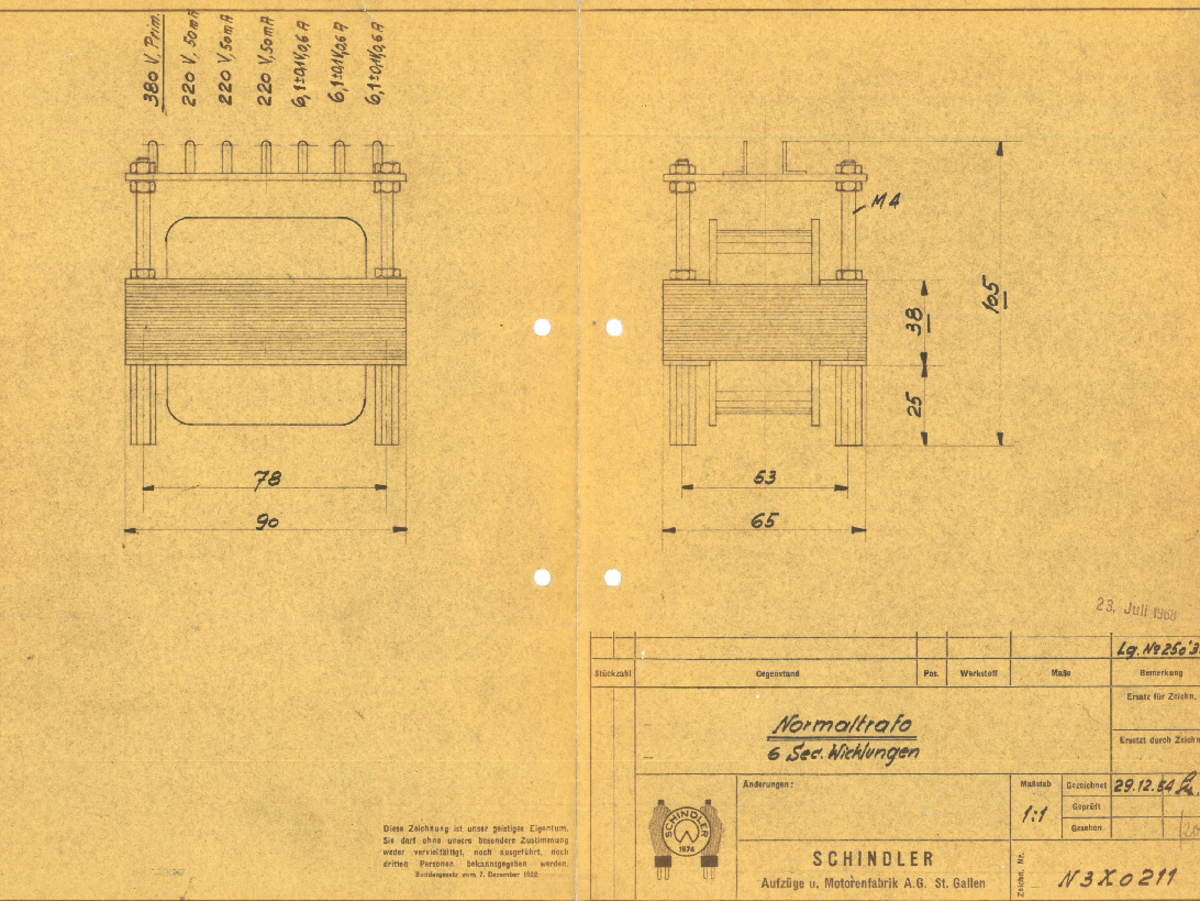

It was in the middle of the industrial revolution in 1882 when the two researchers Lucien Gaulard and John Dixon Gibbs in London were awarded English patent no. 4362 for the construction of the first transformer. At the time, it was not yet known as a transformer, but was referred to as a secondary generator.

What impact did the invention of the transformer have?

"The decline in direct current and the increased use of alternating current meant that the transformer became more important, as it only works with alternating current. Previously, it was only possible to operate a higher output if the energy source - in Switzerland mostly energy from hydroelectric power stations - was located directly next to the place of use. This is why the large factories, such as BBC in Baden or Georg Fischer in Schaffhausen, were always built next to rivers."

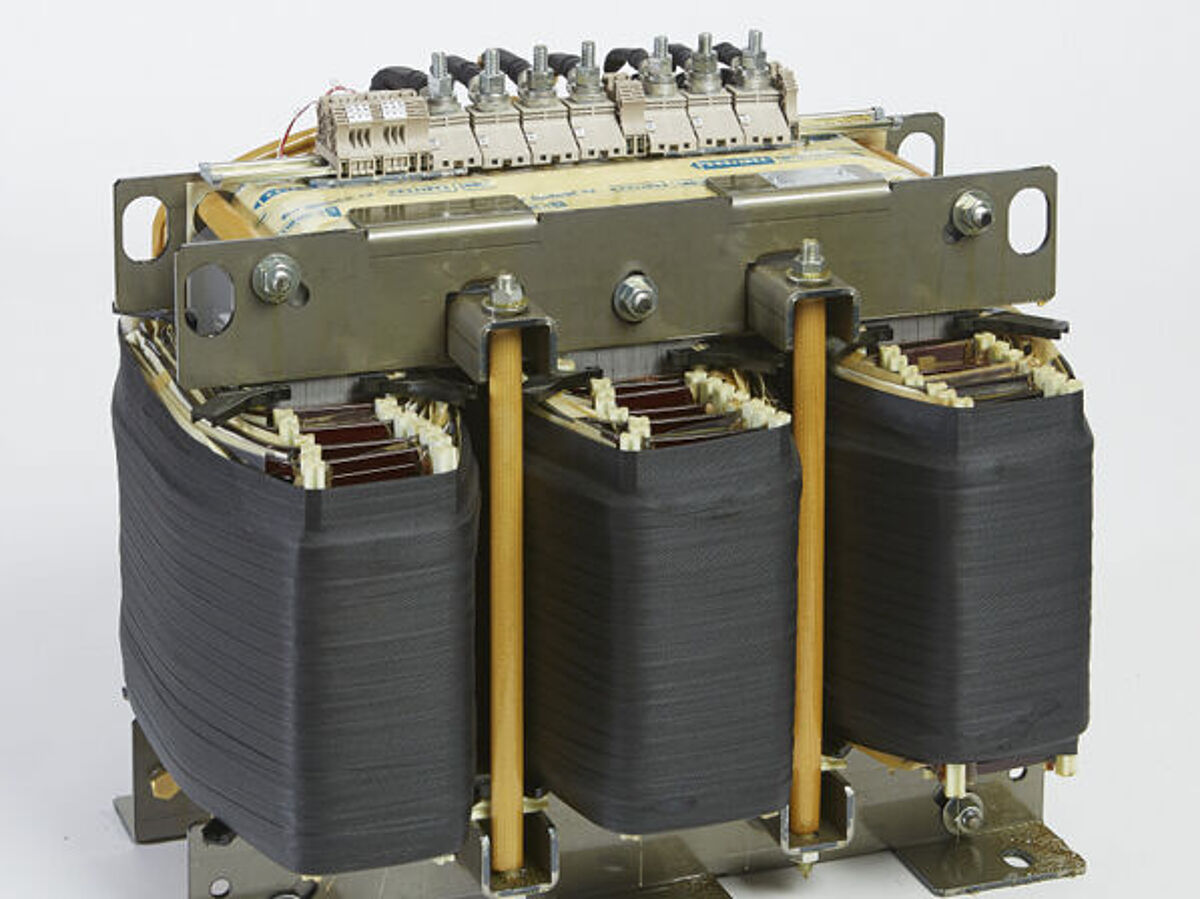

The use of alternating current and (grid) transformers made it possible to build extensive power grids for the first time. At the beginning, this was a maximum of 3,000 volts. Haak adds: "The first three-phase transformer was built in 1890. One year later, the first long-distance transmission in Germany took place with 15,000 volts from Lauffen am Neckar to Frankfurt am Main, a distance of 175 kilometres."

How has the transformer developed since then?

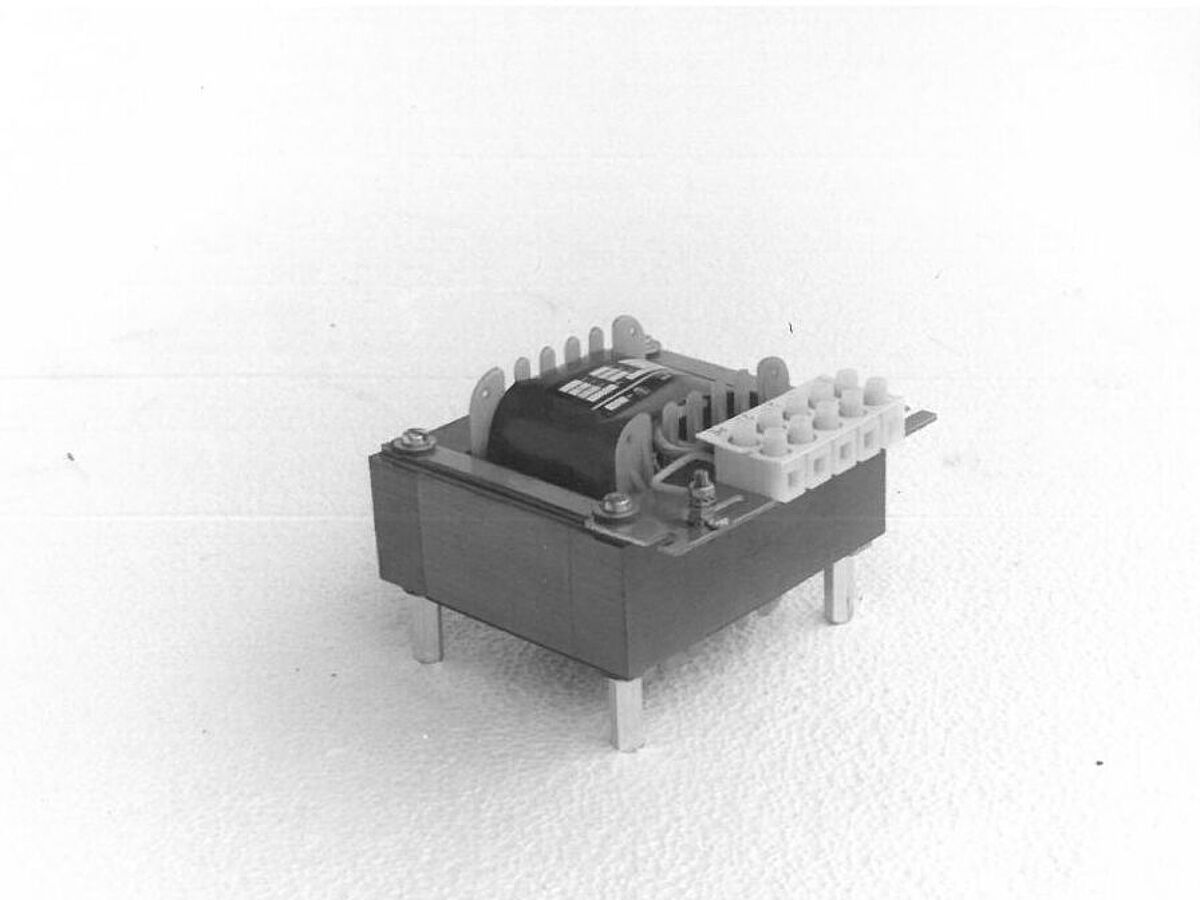

"Since the discovery, the technical principle has remained the same. Even the materials are practically the same. You could build a transformer core with nickel and cobalt instead of iron, but that would be far too expensive. The alternatives to copper conductors are aluminium, gold and silver. The latter are also known to be expensive. Although aluminium is cheaper and lighter, the ohmic losses are higher, which is why the use of aluminium only makes sense in very large systems."

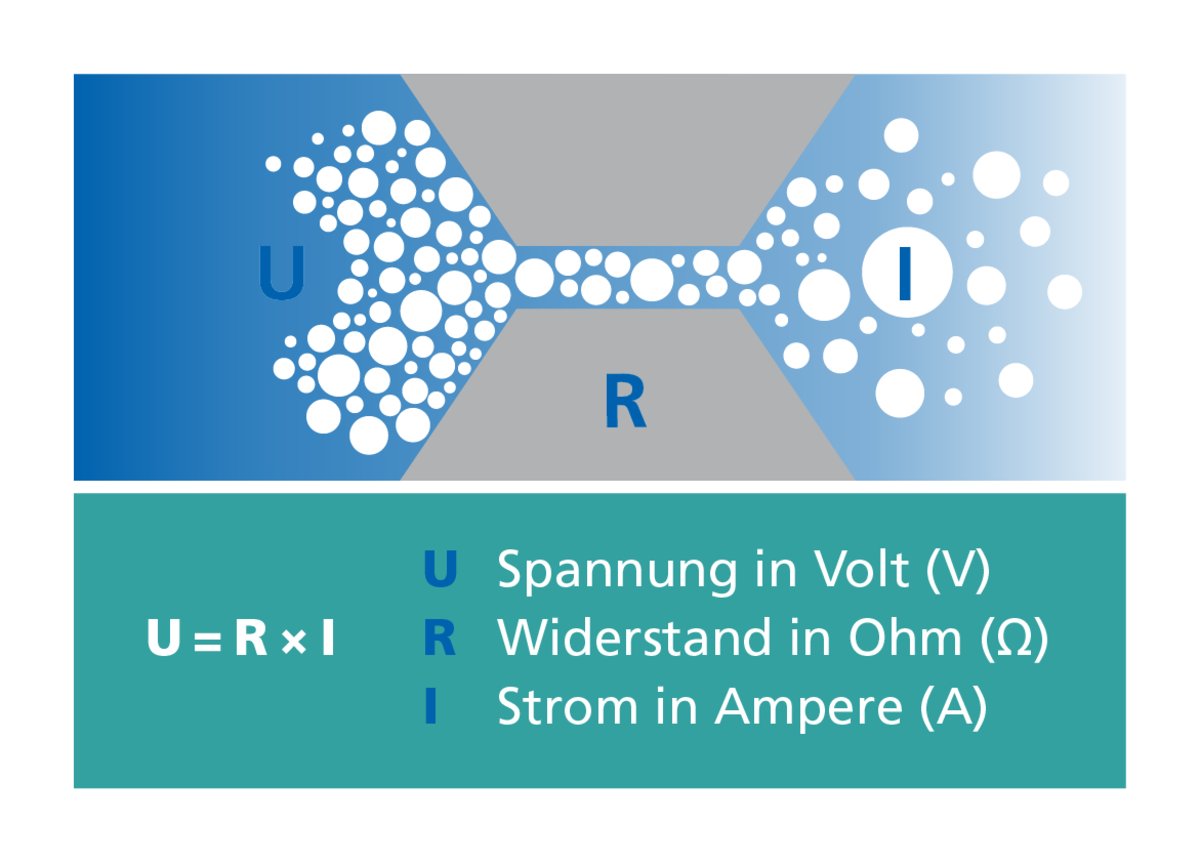

Ohmic losses

These occur in every electrical conductor as soon as current flows. The amount of loss is directly dependent on the electrical resistance of the conductor and the amount of current. The energy that is lost is in the form of heat.

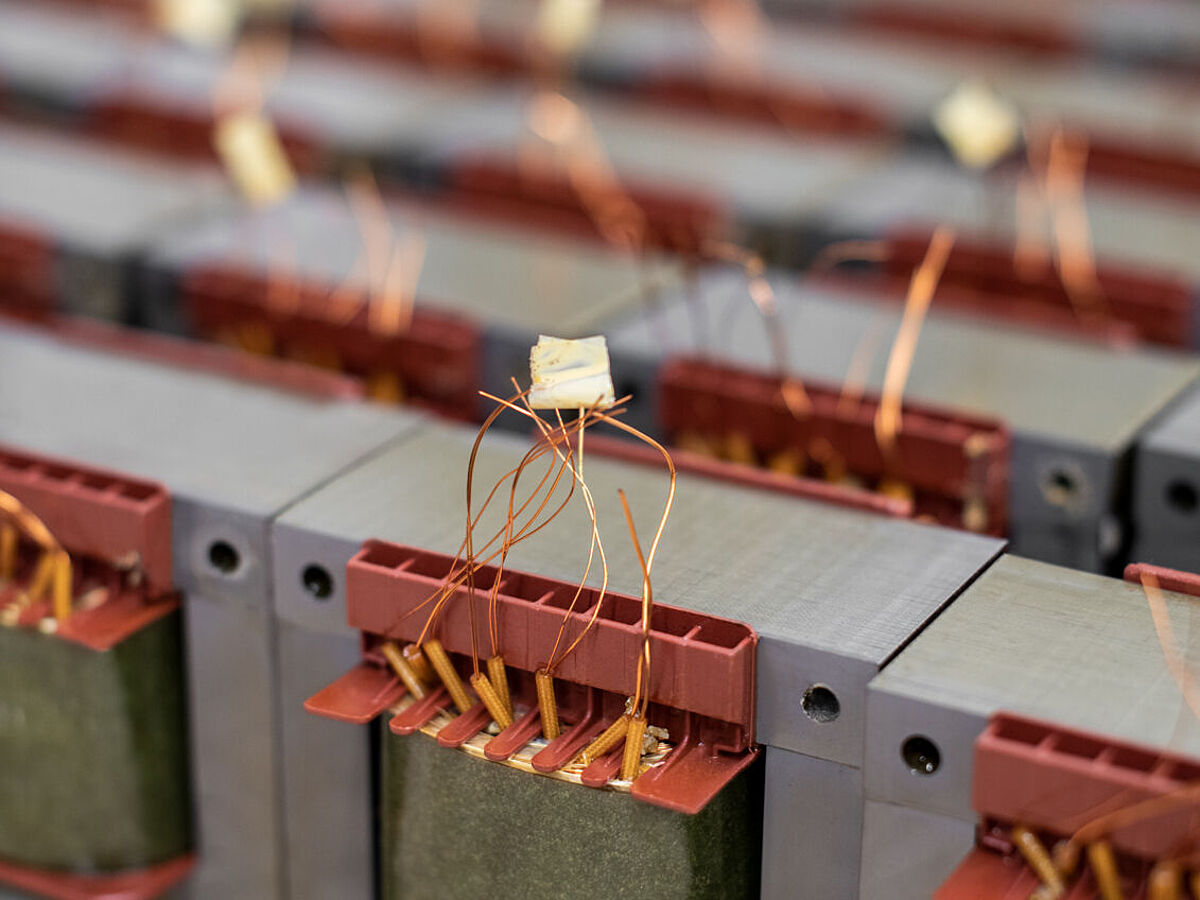

Major advances in insulation

Where great progress has been made in the last 50-60 years is in the field of electrical insulation. Initially, natural materials such as wood, cork or cellulose were used as insulating materials. Today, these are highly developed chemical plastics such as PE polyethylene, PES polyester and, alternatively, mineral materials such as glass and mica. These materials offer higher temperature resistance and insulating properties, making them more durable and safer to use.

Haak explains that the improved insulation results in higher voltages. However, only 3-5% of a transformer consists of insulating material. This small amount can also be seen as an advantage. "Because," says Haak, "copper and iron are metals that are 100% recycled. The insulating material, on the other hand, is either thermally utilised or remains as residual waste."

So the transformer from back then is still the same as it is today?

"Not quite, because there has been progress. Refined calculation methods have led to increased utilisation of materials. The keywords here are PC-based calculations and heating models."

Other developments in recent decades?

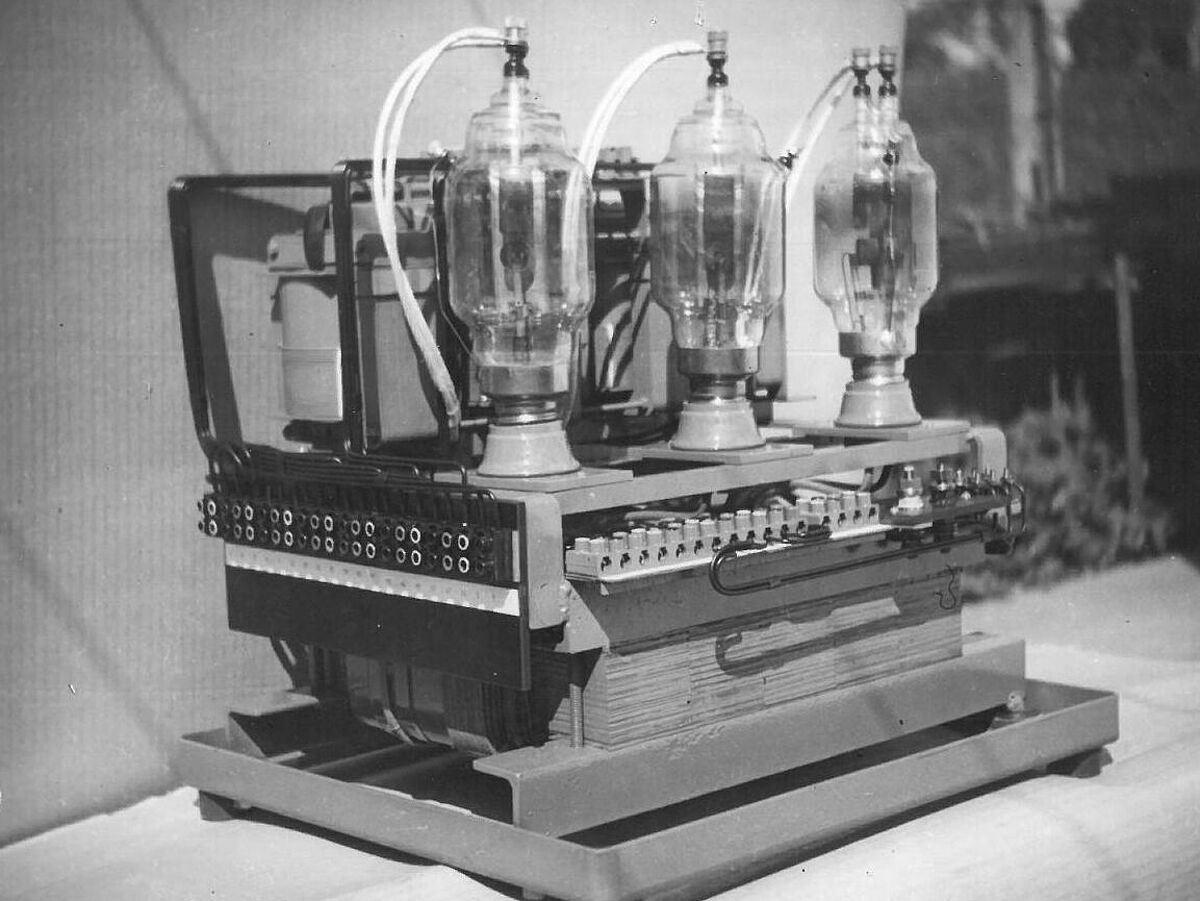

"The development of electronic switches and semiconductors, e.g. transistors or thyristors, led to new possibilities in circuit technology. Electronic circuits, such as step-up or step-down converters, made it possible to adjust voltages. This means that electronic circuits can also be used for voltage adjustment or transmission in addition to classic transformers."

Why do we need these electronic circuits?

"A transformer is always "passive", i.e. the input and output voltage are always the same. This "passive transformer" has become controllable thanks to the electronic circuit. The passive transformer thus becomes an active component that can control and regulate the voltage. Bächli AG is working closely with a well-known technical university in Switzerland and has produced the first samples for testing inductive components in conjunction with electronic circuits."

"Even though the invention of electronic circuits (semiconductors) initially made it seem that transformers were no longer needed, this was fortunately not the case for Bächli," says Haak with a laugh. Even the most modern devices and energy supply networks cannot manage without transformers."

How was it possible to make transformers smaller and smaller?

"The further development of electronic circuits, such as half- and full-back converters, has made it possible to operate transformers at significantly higher frequencies. Thanks to these, significantly smaller transformers can be built. For example, the power grids of aeroplanes operate at 400 Hz - compared to 50 Hz in the general supply network."

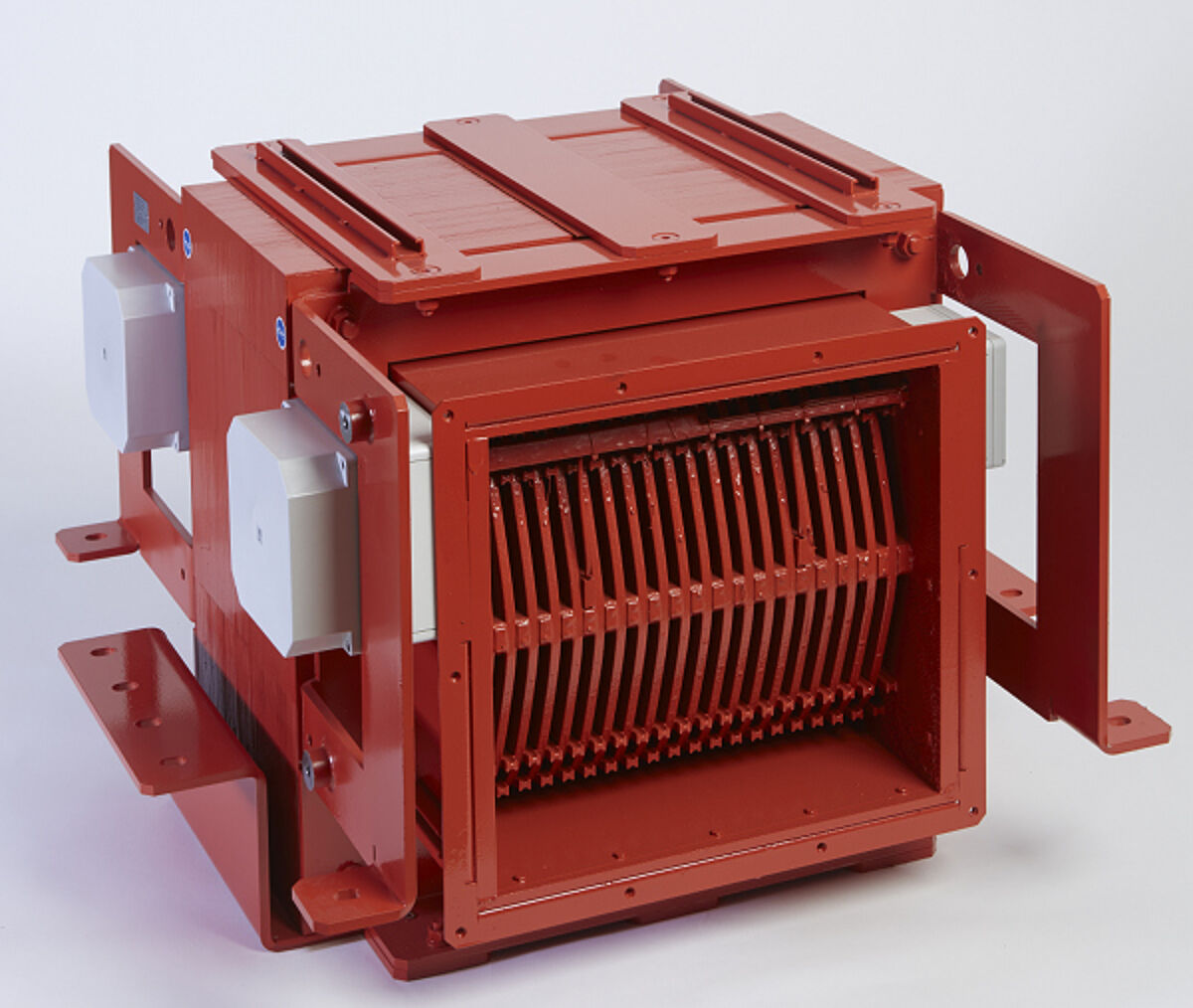

It is interesting to note that 400 Hz has not become established in modern railways. Haak suspects that the reason for this is the historical development of railway electrification. In contrast to aeroplanes, railways operate at 16 2/3 Hz. Their transformers are three times as heavy as mains transformers.

Let's talk about the trends in transformers. Will there be any major innovations in the near future?

"In the context of the discussion about CO2 emissions, the aim is to transmit energy with low losses."

The major trends in transformers are Increased efficiency and sustainability.

One example: mobility in public transport is being expanded more strongly throughout Europe. Here we see many tasks and development potential for our company Bächli. Modern vehicles are no longer powered by petrol or diesel, but electrically with a battery or fuel cell. These vehicles always require a transformer for energy transmission, adaptation or control. The transformer plays a major role on the road to electrification.

Today, every transformer increasingly contains an electronic circuit. Will Bächli also produce these circuits in the future?

"Bächli specialises in transformers. We are not the ones who build the electronic circuitry. Others are the specialists, for example ABB and Siemens, to name two big ones. However, these specialists always need a customised transformer."

What challenges does Bächli face?

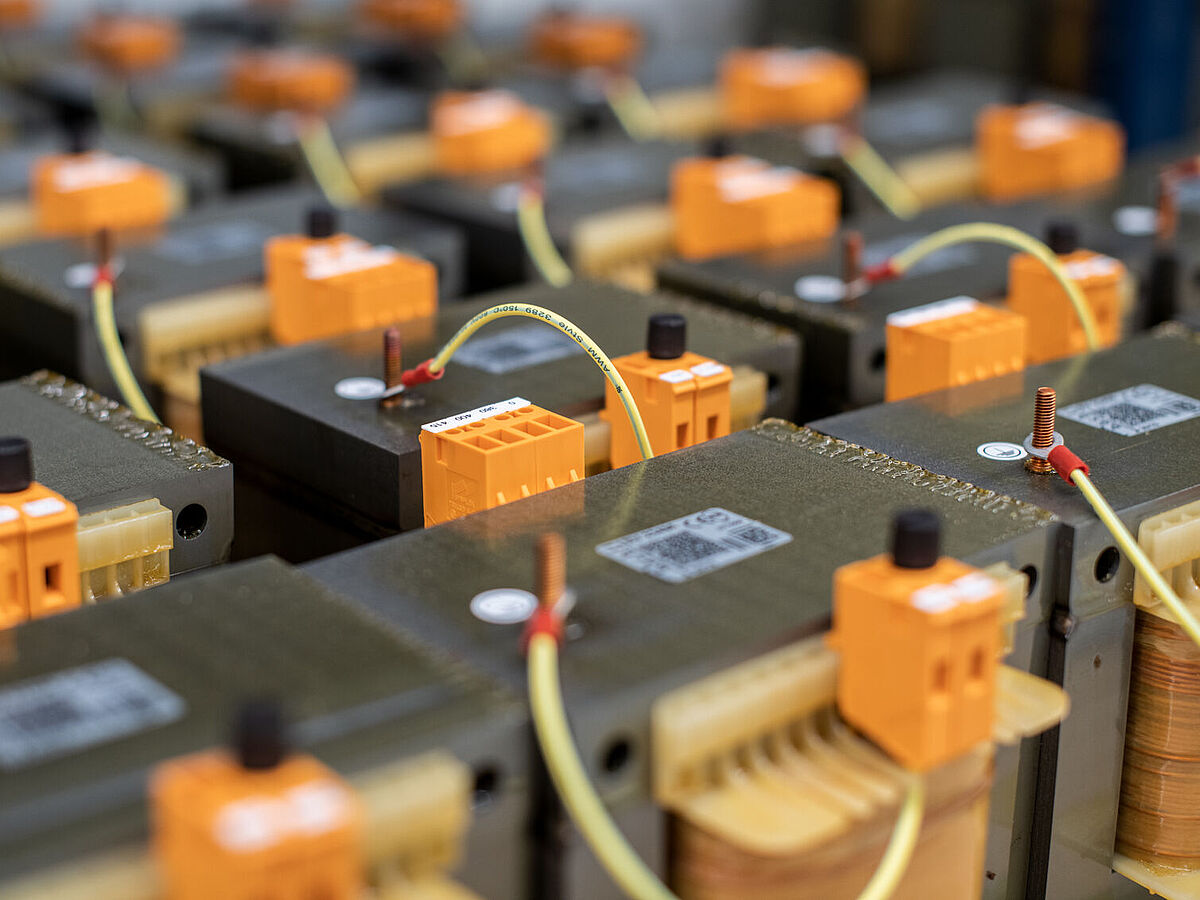

"You could say that the principle and the product "transformer" per se are technically simple. But every transformer that Bächli builds for a customer has specific requirements. The necessary calculations are highly complex, time-consuming and require a great deal of experience.

Bächli AG has its own calculation programmes, which have been continuously developed and improved over decades of experience. We work together with a renowned technical university in Switzerland to develop even better calculation models."

Where is Bächli heading?

"We want to build highly efficient transformers with maximum efficiency."

Our transformers already achieve an efficiency of 95%. The goal is 99%!

Haak gives an example. A grid distribution transformer works 24/7 and even the smallest improvements have a major impact. Be it in terms of costs, but also in terms of energy losses that nobody can afford. Keywords here are "unicore technology", which ensures low-loss iron cores, cage clamps or push-in connections, which enable simple installation. Other areas of research include the above-mentioned inductive components in conjunction with electronic circuits such as medium-frequency transformers.

There are interesting starting points for components with water cooling. Cooler operating temperatures can further increase efficiency. Bächli AG is investigating this possibility, but has not yet manufactured any water-cooled components.

Will your target group change in the future?

"We already serve all industries with our transformers, because electrical energy is needed everywhere! Sustainably generated, it is the most environmentally friendly source of energy. Even a professional coffee machine contains a Bächli transformer."

Our target group will continue to be all industries tomorrow.