Frank Hanisch on strengths & future challenges

The technical director of Bächli AG in an interview about the strengths of Bächli AG and the technical challenges of the future.

Together with his team, Frank Hanisch is responsible for the technical design, calculation and construction of Bächli products. With over 30 years of experience in the transformer industry, he specialises in all challenging issues.

What solutions does Bächli offer the railway sector?

Modern rail transport systems aim for safety, efficiency and a good environmental balance. Efficient electrotechnical components are the basis for reliable energy control. With our solutions, customers can draw on many years of experience. The wide range of tried-and-tested products, combined with the innovative strength to develop new solutions, make Bächli the technology leader for chokes and transformers in railway technology.

In close co-operation with its customers, Bächli develops innovative solutions that make a significant contribution to the customer's long-term success thanks to their outstanding performance features tailored to the customer's needs.

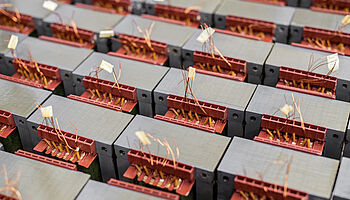

Our expertise lies in the manufacture of all inductive winding goods, such as chokes, transformers and filters. They can be installed in/on/under the train or used in the railway infrastructure (track, signalling systems, tunnel lighting, etc.).

How can your solutions help train manufacturers and operators to become more environmentally friendly?

By offering energy-efficient products, such as products from the Smart-E-Power® range, which have significantly lower losses. In addition, the end customer saves electricity and thus reduces their energy costs, which is of course a positive side effect.

With an energy-efficient product, it is possible for Bächli to significantly reduce losses. At the same time, sustainable materials are used, which have a long service life and are sometimes even degradable or reusable.

Compared to a standard product, this can make a significant difference for the customer in terms of price. By saving on electricity costs and minimising maintenance and servicing costs, customers have attractive opportunities to reduce their costs and do something good for the environment at the same time. After all, an energy-efficient transformer produces much less CO2.

What is the Smart-E-Power® standard, when was it developed and what are its key benefits for the railway sector?

The name Smart-E-Power®is about 10 years old. At Bächli, products with very high energy efficiency are summarised under this name.

The extremely efficient Smart-E-Power® transformers are designed to minimise load losses and have a high overload tolerance. The highly efficient iron core and the use of special sheet metal technology give the product unique capabilities. It saves losses and therefore electricity, making it much more efficient than a normal winding material. An efficiency of over 99% can be achieved from as little as approx. 25 kVA, and it is also very quiet in operation.

Furthermore, the customer can also plan with a very compact transformer, as the high-quality materials make a compact design possible.

If the criterion of lifecycle costs is taken into account, the Smart-E-Power® is absolutely the best product. The costs summarised over the entire life cycle already show a positive balance after a short time (see Bächli AG article). The higher purchase costs, due to the high-quality materials, the complex technology and the high-quality construction, are paid back after just a few years, as this enables large potential savings in electricity costs. Maintenance and servicing costs can also be reduced to a minimum with an energy-efficient product.

Is this standard used for all Bächli products?

No, we are able to manufacture our products in four different designs. Depending on the customer's requirements, we focus on a different feature when designing the product.

- The Smart-E-Power as a very energy-efficient solution with minimal load losses.

- The sustainable series, which is suitable for a short-term harmonic trend and is characterised by a high degree of efficiency.

- The compact products, which are characterised by their low weight and compact design, can solve the customer's space or weight problems.

- And the standard version, which is particularly suitable if no specific requirements need to be met.

For all four types, we start from the electrical parameters of the customer's specification and orientate ourselves on the currently applicable standards and laws. If you would like to find out more, please visit our homepage and we will be happy to advise you personally.

Can you talk about a current project you have carried out in the railway sector?

Every day we develop new customised solutions and produce transformers, chokes and filters of the highest quality.

As an example, we would like to mention a current project that we are currently working on with a major train manufacturer. For over six months now, we have been working with the customer to develop a very compact and energy-efficient mains choke. A few weeks ago, we were able to start series production thanks to the successful FAI.

This is the largest mains choke that Bächli has ever built. The 1500V DC mains choke with a total weight of over 1.2 tonnes is very compact and low-loss despite its size. Thanks to our design, we were able to halve the maximum requirements for the total weight. The weight savings mean that less energy has to be used for locomotion, thus reducing energy consumption. At the same time, care was taken during engineering to use high-quality materials in order to reduce energy losses. Thanks to the resulting efficiency gains, the customer was able to switch to smaller fans, which brings further savings in the acquisition costs and energy losses of the purchased part.

How do you see the railway sector developing over the next 5-10 years in terms of sustainability/electrification?

I see great potential. Everyone is making progress in this area, especially the railways. There is also still a lot to do in terms of the rail network, as some lines are not yet electrified.

Unfortunately, despite all the activities and efforts, some companies are still not focussing enough on sustainability. The initial costs of procurement still take up too much space when awarding contracts. It would be better to focus on the entire life cycle costs, as this would put everything in a different light and bring major benefits.

Despite all the efforts and good intentions, the railway sector is a large industry with a long tradition, and it takes time to initiate and implement changes.

What key challenges is Bächli currently trying to solve when it comes to the railway sector and sustainability?

Manufacturing energy-efficient, durable products that are as maintenance-free as possible.

Today it is possible to use transformers that do not require external ventilation and are therefore maintenance-free. This massively reduces the overall maintenance and servicing costs. But as an engineer, it is a great challenge to calculate transformers that do not require forced cooling, because fans normally have to be installed. This is because it must be ensured that clean air is used as a cooling element. Filtering is therefore required to protect the transformer from dirt particles such as sand, salt, snow, etc. The fans have to be serviced or replaced at a predefined interval, and the vehicles have to be taken to a workshop to do this. This results in downtime for fleet operators, which causes high costs.

By using an energy-efficient product, it may be possible to dispense with external cooling, as there is no need to monitor the cooling circuit.

Due to the use of housings and energy-efficient materials, the purchase price of a Smart-E-Power® product is higher. However, as already mentioned, this energy-efficient design means that various elements can be dispensed with (maintenance costs, the cooling circuit, high total weights, etc.), so you can very quickly achieve a positive energy balance and a nice side effect is that the cost balance is also more positive. It is important to look at the total life cycle costs, as this quickly reveals where there is potential and also how quickly a payback can be realised. As the maintenance costs are only incurred by the end customer, the train manufacturer must pass this argument on to the end customer. Only by analysing the total costs can a real picture emerge.

It would be easier for us as Bächli engineers if we were integrated into the projects at an earlier stage. This would allow us to exert much more influence and advise the customer when it comes to optimisation proposals for the surrounding components. This makes it possible to design the entire system more efficiently.

What does the future hold for Bächli and what will you be working on next?

We see our future in developing solutions with the customer. By analysing the technical specification and the requirements for energy efficiency, space, weight, etc., we can design and manufacture a product that is ideal for the customer. In order to realise the full potential, it would be important for us to be integrated into the projects at an earlier stage.

In order to be prepared for the future in terms of research and development, we work closely with universities and Switzerland's leading university for electrical engineering. This co-operation and the resulting projects encourage us to deal with a wide range of topics and show us the right steps for the future, which is an essential topic in engineering but also for the entire company.

We can look forward to many exciting and challenging projects in the future. Dealing with new, complex and individual specifications makes our day-to-day work exciting and the subsequent successful realisation of the products fills us with pride.